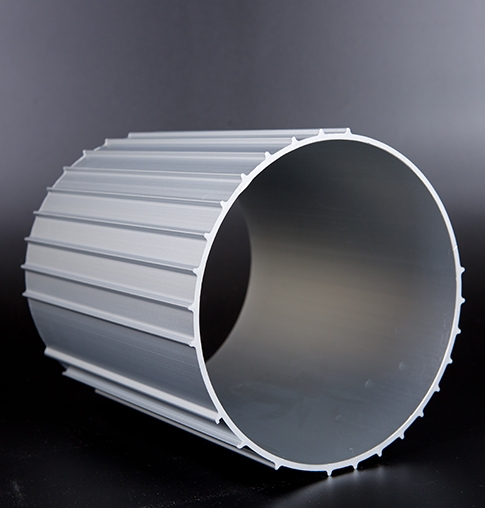

Aluminum extrusion processing technology is mainly forward extrusion, reverse extrusion, mixed extrusion. Its basic principle is to use the method of applying external force to the extruded metal material, so that the metal material in the pressure container is subjected to three ways of compressive stress and plastic deformation, and extruded from a specific die hole, get a certain section shape, size and performance of the extrusion product molding process. In order to make the metal material deformation, to overcome the bonding force between metal atoms, that is, to overcome the force of metal bonds between metal atoms, and make it slip. The metal is transformed from elastic deformation stage to plastic deformation stage under the influence of numerical simulation and optimization design of die structure.

Therefore, the extrusion processing technology has the following three basic conditions :(1) the metal must be in a state of three-way compressive stress; (2) Establish enough stress value, so that the metal can produce plastic deformation; (3) There are die holes or gaps that can make the metal flow out, providing a smaller resistance direction.

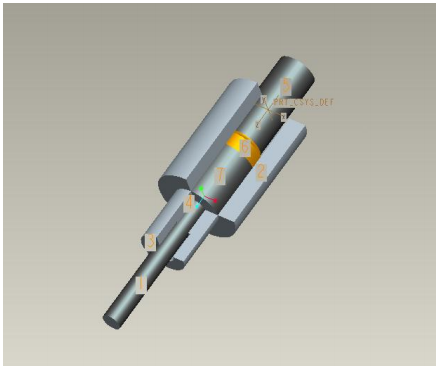

In the extrusion molding process, the extrusion pressure transferred to the extrusion shaft , through the extrusion gasket , so that the metal blank in the extrusion cylinder is in a state of three-way compressive stress, when the force by the blank reaches a certain value, the blank will be extruded from the hole of the mold, forming extrusion products. In the extrusion process, the direction of the extrusion shaft forward and the direction of the metal flow is consistent, known as forward extrusion, and conversely known as reverse extrusion.