When it comes to CNC machining, planning is critical. Often, CNC machining designs and projects can become unnecessarily complex - and as with almost everything in life, time is money. At Liangyin, we understand that some designs require precise details that can't be simplified, but if you want to reduce costs and have the design flexibility to change design features, this blog post is for you.

By understanding the CNC machining process and the factors that affect price, you can reduce the cost of your machining project while maintaining or improving functionality. Manufacturability is the level of complexity of the manufacturing process required to make a given part. In essence, the higher the manufacturability, the lower the cost.

This blog post will review some of the key ways you can reduce the cost of CNC machined parts and enclosures.

Material Costs

In machining, the harder the material, the more difficult it is to machine. This is because we must use less time efficient processes and cutting parameters.

We recommend using 6061 aluminum for CNC jobs where you are tolerant of the material. This type of aluminum is typically used for CNC machining. 6061 aluminum is ideal for CNC projects because it offers a balance of toughness, strength, corrosion resistance, and most importantly, excellent manufacturability.

Design

The more you can simplify your design, the lower your project costs will be. The details, dimensions and geometry of your project can have a significant impact on cost. Complex, highly detailed parts may require multiple setups, resulting in higher costs. Some complex projects with multiple faces may be cheaper with appropriate modifications.

The following are some design tips to help you reduce costs.

◭ If your part has holes or slots on all faces, consider moving these details to the same face whenever possible. This will reduce setup costs and save you some money.

◭ Small features such as holes and slots can lead to complex and expensive designs.

Minimize removal of bulk material

Sometimes part design changes can have a dramatic impact on the amount of material removed from a part. Most parts are made from bar stock, which is initially rectangular or cylindrical in shape. The amount of stock removed directly affects the price of your design.

Think about the smallest box that fits your finished part (this can be rectangular or cylindrical, whichever fits your finished part best). The volume of the box that does not contain your part represents the amount of material that needs to be removed to make your part. The more "empty" space you have means more material needs to be removed, which in turn can drive up the price of machining your design. Certain shapes can reduce the amount of empty space, and modifying your design to these shapes can reduce costs.

One way to eliminate the cost of large amounts of air is to break down your design into many simpler parts that fit better into the "box". This will minimize material removal and save you money.

Tolerances

Our typical minimum tolerance on CNC machined parts is ±0.005". While we can achieve tighter tolerances, larger tolerances will save you money because tighter tolerances mean higher manufacturing accuracy is required to manufacture your design.

Tolerances should be kept as tight as your design will allow to improve manufacturability and thus reduce costs. If your design requires tighter tolerances, we can provide them, but we recommend that you keep your tolerances at least ±0.005 inch or more to minimize costs.

Inside Corner Radius

The inside corner radius you choose will not only have a huge impact on the machining efficiency of your part, it will also affect the cost of your design. By using the largest possible radius for your design, you can both improve the quality of the surface finish and reduce machining costs.

An important tip: The radius of the outside of the part or housing is not limited by the diameter of the tool.

Corner radii should always be as large as your design allows. If you need a smaller radius for an inside corner, the minimum size we recommend depends on the depth of the corner. The deeper the corner, the larger the minimum radius must be.

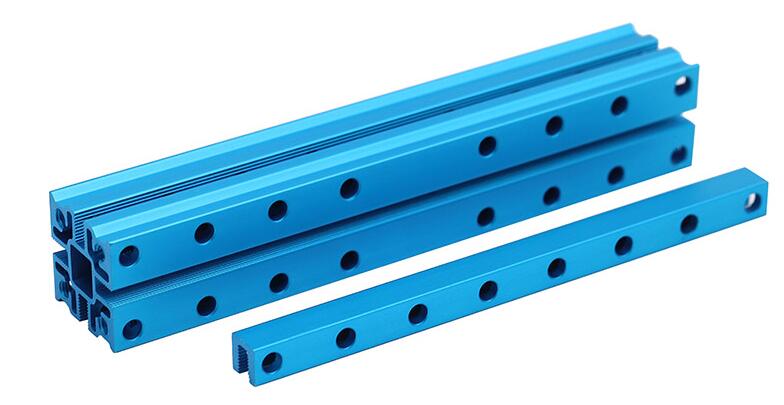

CNC machined off-the-shelf housings

Another way to reduce the cost of CNC machining projects is to use off-the-shelf (OTS) housings. We have a wide variety of die-cast housings that we can CNC machine and customize for you.

The cost of an OTS is much lower because no material is wasted in a custom die-cast OTS housing, whereas a custom CNC machined housing is made from a solid block of material. When you use an OTS housing, we can cut custom holes in the housing to meet your design requirements, which will save you money.

If you would like Liangyin to customize an OTS housing for your project, please learn more about our customizable die-cast housings.

Conclusion

When designing a CNC machined part or housing, consider the complexity required to manufacture the part and how to simplify the design. Remember, the higher the manufacturability, the lower the cost.

If you have any questions, please contact our team! During your design phase, we can help you avoid designing unnecessary and expensive parts.

Our mission is to find the right solution for you and keep your project moving forward so you can meet your deadlines and keep innovating.