There is a wide variety of ultra-performance straight fin, slant fin, and pin fin extruded heat sinks. These high aspect ratio heat sinks are ideal for applications where there is adequate airflow to take optimum advantage from these designs.

Extruded aluminum heat sinks are the most cost-effective solutions for most electronic cooling applications. ATS offers a wide variety of aluminum profiles for custom heat sink fabrication and other applications. ATS extrudes its heat sink profiles from high performance, smooth surface aluminum alloy 6063. Standard bar lengths are 300mm (11.8in), for easy, cut-to-length fabrication of prototypes and custom sizes.

LED heat sinks are used across the globe because of their energy-saving advantages. An LED’s performance, similar to any other semiconductor device, is temperature sensitive. Higher temperatures cause degradation in the working life and light emittance of the LED. Our heat sinks are able to cool their LED lights for their highest performance and efficiency.

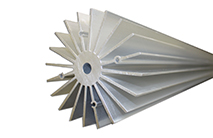

Ultra-performance Slant Fin heat sinks are available for component sizes 10x10mm to 60x60mm. Heat sink height ranges from 2-25mm in 1mm increments. The Slant Fin design offers additional surface area, and therefore higher performance for applications that can accommodate larger fin-to-fin spacing. Because they are fabricated from extruded aluminum, Slant Fin heat sinks have minimal thermal resistance from their base to their fins, and are lightweight.

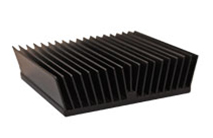

Straight Fin extruded aluminum heat sinks are available for component sizes 10x10mm to 60x60mm. Heat sink heights range from 2-25mm in 1mm increments. Their high aspect ratio means there is a greater density of fins in a given footprint than more common heat sinks. The Straight Fin design offers an excellent cooling solution for spatially constrained PCB layouts. The ratio of tall, straight fins to their small footprint base improves thermal performance and saves space. The extruded aluminum minimizes thermal resistance, reduces weight and saves cost over alternative (e.g. copper) heat sinks.

Pin Fin extrusions are ideal cooling solutions for spatially constrained PCB layouts when the airflow direction near the device is ambiguous. Pin Fin heat sinks have high aspect ratios for applications where there is adequate airflow to take optimum advantage from these designs. The pin fin layout provides low pressure drop characteristics. The combined large surface areas of the pins and base increases overall heat sink performance. Heat sink solutions are available for component sizes 10x10mm to 60x60mm. Heat sink height ranges from 2-25mm in 1mm increments.